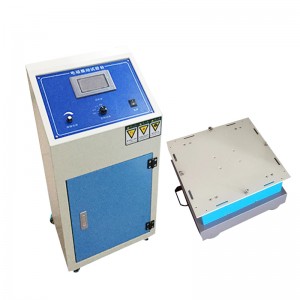

Metal welding residual stress elimination machine Vibration aging tester Vibration tester Copper plate welding internal stress elimination machine

Scope of application:

Vibration aging meters are mainly used in aerospace, automobile manufacturing, shipbuilding, machinery manufacturing and other fields. These fields have the highest requirements on the accuracy and stability of components. As an effective stress relief method, vibration aging can significantly improve the dimensional accuracy, stability and service life of components. The vibration aging meter uses the principle of resonance to reduce and homogenize the residual stress generated inside the workpiece during welding, casting, machine tool processing, and mechanical manufacturing, thereby effectively improving the strength of the workpiece, reducing the occurrence of deformation and cracking, and making the workpiece The accuracy is more stable.

Equipment advantages:

The application of vibration aging instrument not only improves the mechanical properties of components, such as strength and fatigue life, but also reduces stress corrosion, and prevents or reduces the occurrence of micro cracks caused by heat treatment, welding and other process. In addition, because the equipment is simple and easy to move, the vibration aging instrument can be used for on-site treatment at any site, without being restricted by the size and material of the component. Vibration aging technology can be used for components ranging from tens of kilograms to hundreds of tons. Especially when some large components cannot be treated with heat aging, vibration aging has greater advantages.

Product Overview:

Vibration aging uses the principle of resonance to eliminate and homogenize the residual stress of metal castings, forgings, welded structural parts, non-ferrous metals and other parts to prevent the deformation and cracking of the parts. Vibration aging is a new process for eliminating residual stress. It is based on the principle of harmonic resonance. It uses a suitable excitation device to rigidly fix it in the appropriate position of the vibrated workpiece. By adjusting the excitation force and frequency, the workpiece is forced to vibrate within a certain period of external force and within the resonant frequency range. After a certain period of time, the purpose of reducing and homogenizing residual stress and dimensional stability can be achieved.

Features:

1. True color LCD dynamically displays various curves and data, detecting and mastering the entire aging process in real time.

2. Automatically determine whether the process parameters are appropriate and provide a revision plan to achieve human-machine dialogue.

3. It has multiple working modes of manual frequency sweep, manual aging, fully automatic frequency sweep, fully automatic aging, and process parameter preset.

4. The dynamic tracking function can ensure that vibration processing is always carried out in the sub-resonance area required by the standard.

5. Using pulse width modulation technology, it has strong anti-interference ability.

6. Automatic frequency sweep function automatically selects the frequency sweep range and eliminates human participation.

7. Can scan multiple resonance points and automatically select the aging frequency.

8. It has functions such as characteristic curve analysis and automatic diagnosis prompts for common faults.

9. The circuit has the functions of wide phase shift range, automatic voltage stabilization, and overcurrent cutoff protection.

10. All imported components minimize the failure rate and significantly increase the service life of the equipment.

11. High-speed thermal printer, Chinese display. Comprehensive printing of aging curves and data facilitates archival management by relevant departments.

12. Strong and weak current isolation ensures safe operation.

13. Multiple protection functions such as overrun protection, overload, overcurrent, and overvoltage protection completely eliminate the danger of on-site operations.

| Name | Liquid crystal automatic vibration aging instrument | ||||

| Model | HJ-K1 | HJ-K2 | HJ-K3 | HJ-K4 | HJ-K5 |

| Weight | 10KG | ||||

| Dimensions | 43mm*36mm*16mm | ||||

| Maximum exciting force (KN) | 10 | 20 | 30 | 40 | 50 |

| Speed range (r/min) | 1000-10000 | 1000-8000 | 1000-8000 | 1000-8000 | 500-6000 |

| Weight of workpiece that can be handled (T) | 0-5 | 0-20 | 0-50 | 0-100 | 0-500 |

| Motor power (W) | 1200 | 1200 | 1500 | 2200 | 3500 |

| Speed accuracy (r/min) | ±1 | ||||

| Acceleration measurement range (m/s²) | 0~199.9 | ||||

| Color display function | Online dynamic display of a-n, a-t curves and parameter data | ||||

| Print function | a-n, a-t curves, parameter data and parameter comparison | ||||

| Ambient temperature | Controller -10~50℃, when used in an environment below -10℃, power on for 5 minutes to preheat, exciter: -30~50℃ | ||||

| Relative humidity | ≤80% | ||||