OEM Factory for Programmable Salt Spray Cyclic Corrosion Test Chamber - Hydraulic universal testing equipment – Hongjin

OEM Factory for Programmable Salt Spray Cyclic Corrosion Test Chamber - Hydraulic universal testing equipment – Hongjin Detail:

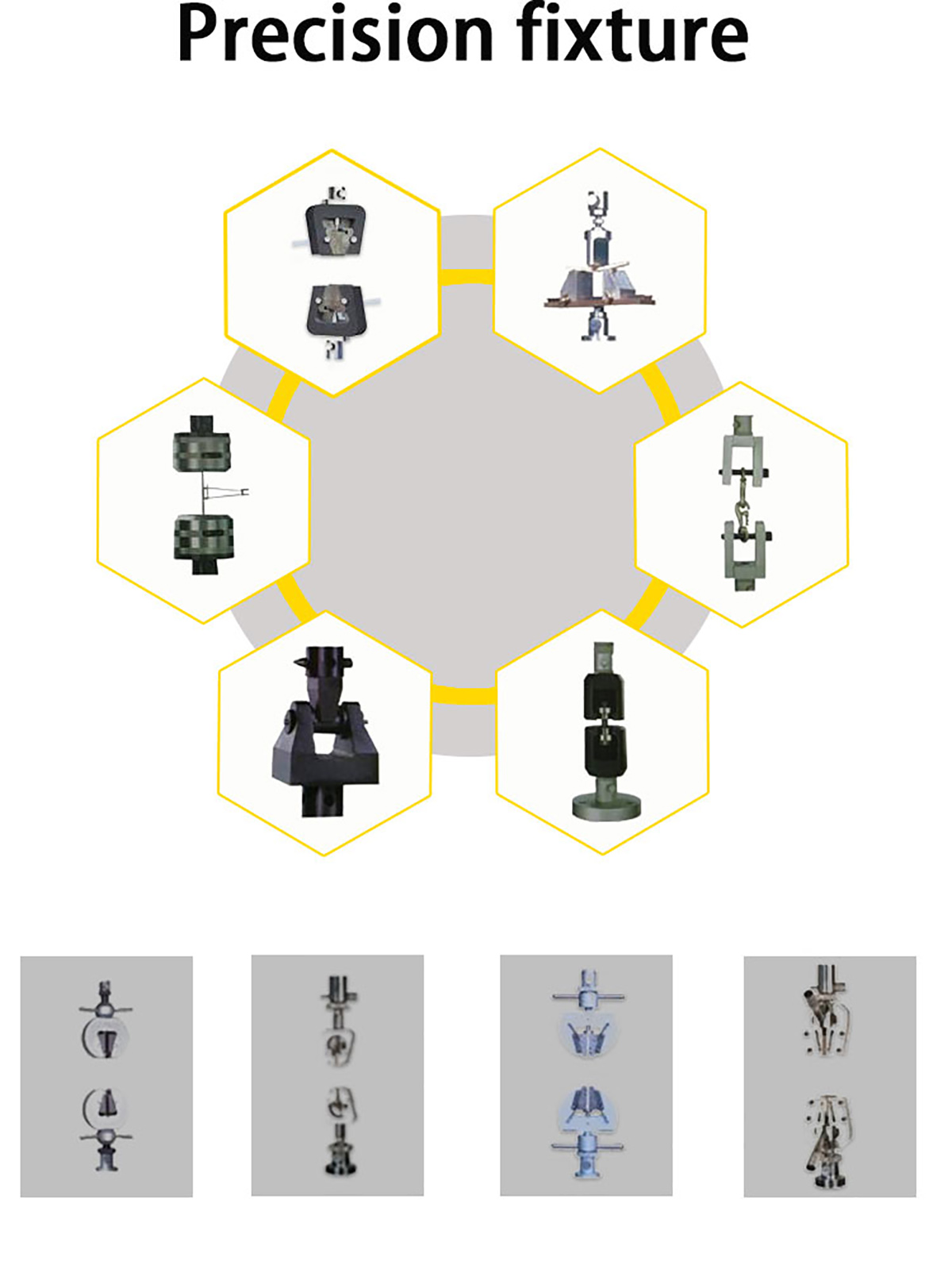

A hydraulic material testing machine that can perform various tests such as drawing, compression and bending. Hydraulic universal testing machine is used for tensile, compression, bending and shearing tests of various metals and non-metallic materials, as well as special tests of some products. The test operation and data processing meet the requirements of GB228-2010 room temperature material metal tensile test method and other standards.

Overview use

Hydraulic universal testing machine is mainly used for tensile, compression, bending, shearing and other mechanical properties of metal, non-metal, composite materials and products. It can also be used for testing and data processing according to GB, ISO, JIS, ASTM, DIN and various standards provided by users. Widely used in aerospace, machinery manufacturing, wire and cable, rubber and plastic, building materials and other industries, material inspection and analysis, is the scientific research institute, colleges and universities, industrial and mining enterprises, technical supervision, commercial arbitration and other departments of the ideal test equipment.

Testing platform

The microcomputer hardware platform can accurately collect and process data in real time. The interface of measurement and control is gentle, intuitive, clear and clear, and easy to operate.

Test force measurement

Load measurement: high precision spokes load sensor and high performance measuring and amplifying system are adopted to ensure the high resolution of the test force. Multiple sensors can be configured according to user needs to achieve wide range of test forces. Displacement measurement:using the 2500P/R high precision photoelectric encoder and the precision screw coaxial rotation, through the digital circuit to realize the weighing power control system. The full digital servo controller is used to control the high performance step motor drive synchronous gear belt and drive the precision screw drive with two pairs of high precision without gap.It has the characteristics of stable load,good low speed performance, no gap, high transmission efficiency,low noise and smooth transmission.

Equipment function

1.Automatic zeroing

2.Auto return

3.Automatic disk saving

4.The testing process, measurement, display and analysis are all finished by microcomputer

5.The data and curves are displayed dynamically with the experimental process.

6. Experimental results can be re analyzed with arbitrary access.

7.After the test is completed, the force and deformation data of the test curve can be found at point by point. 8.Program control and mechanical dual protection function;

9.Overload protection function;

10.Emergency shutdown function;

11.The tensile, compression, bending, shearing, adhesion, stripping and tear tests of the material can be carried out.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. Are your company a trading one or a factory?

Factory ,13years focusing on test instruments field,3 years exporting experience.Our factory is in Dongguan, Guangdong, China

2. After an order is placed, when to deliver?

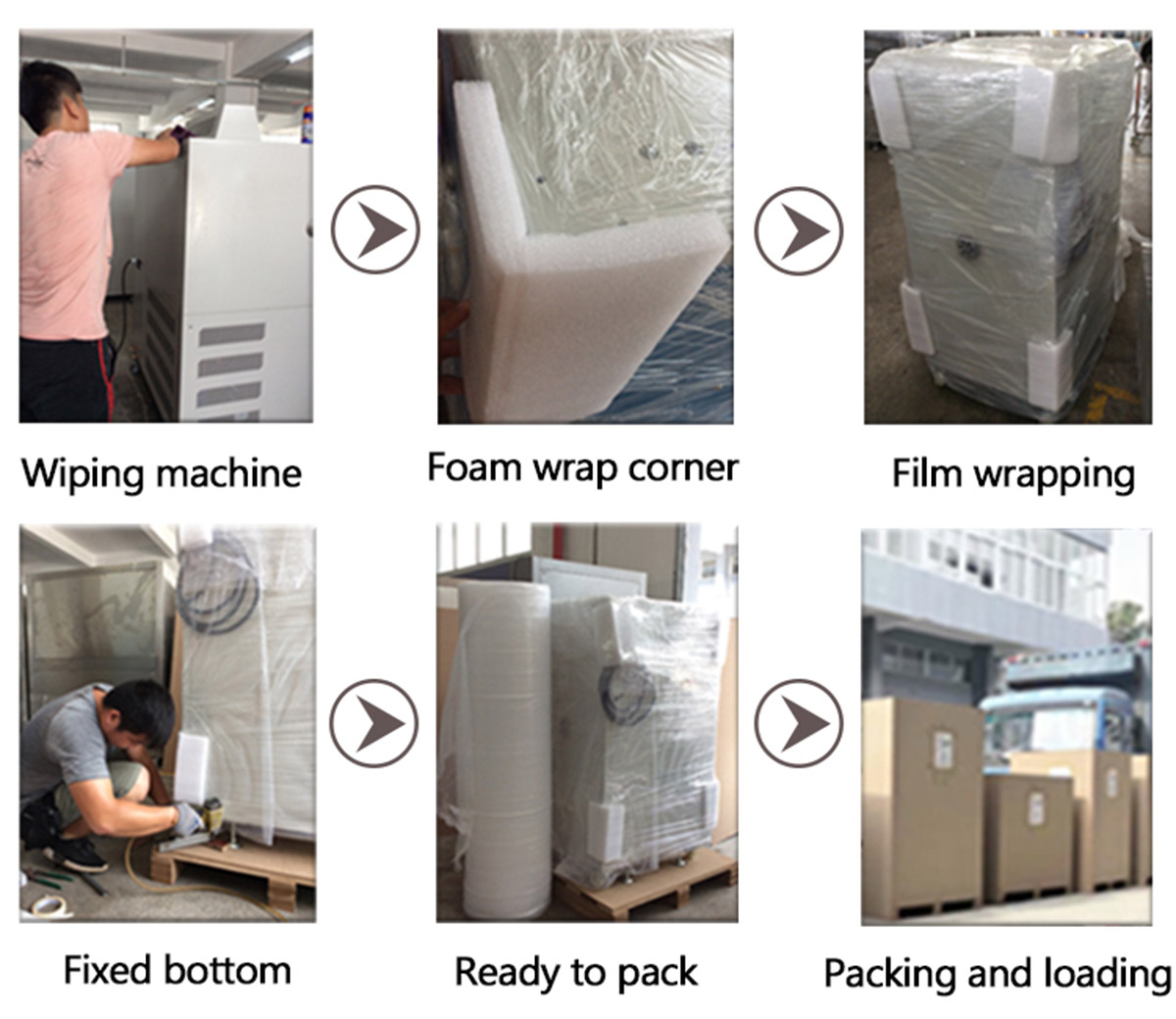

Usually about 15 working days, if we have finished products, we can arrange delivery within 3 working days.

Please note that our production lead time depends on the specific project and the number of projects.

3. What about the warranty with after – sales services?

12 months warranty.

After the warranty, the professional after-sales service team will provide comprehensive technical support to help customers solve problems encountered when using our products, and promptly handle customer problems and complaints.

4. What about the services and product’ quality?

Service: ,Design service,Buyer lable service.

Quality: Each instruments must be carried out 100% quality examination and test, the finished products must through a third party calibration institutions before shipping and delivery goods.

Product detail pictures:

Related Product Guide:

Cooperation

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for OEM Factory for Programmable Salt Spray Cyclic Corrosion Test Chamber - Hydraulic universal testing equipment – Hongjin , The product will supply to all over the world, such as: Barcelona , Moscow , Philippines , We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.